Page 17 - Acoustic Fluid Level Measurements

P. 17

Fluid Level Measurement Applications for Gas Lift Wells 10-1

Petroleum Extension-The University of Texas at Austin

10

Fluid Level Measurement Applications for Gas Lift Wells

In this chapter:

• Unloading status and operating valve identification

• Determining static and producing BHP

• Pressure distribution at steady flowing conditions

• Pressure distribution at shut-in conditions

• Recommended equipment and procedures

• Example acoustic records

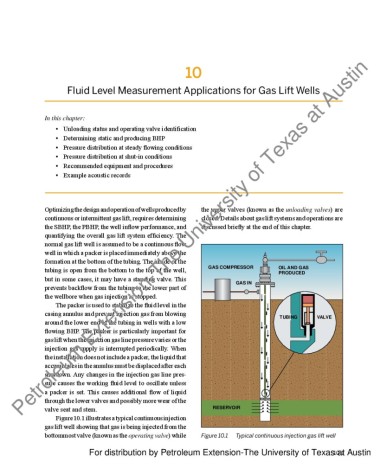

Optimizing the design and operation of wells produced by the upper valves (known as the unloading valves) are

continuous or intermittent gas lift, requires determining closed. Details about gas lift systems and operations are

the SBHP, the PBHP, the well inflow performance, and discussed briefly at the end of this chapter.

quantifying the overall gas lift system efficiency. The

normal gas lift well is assumed to be a continuous flow

well in which a packer is placed immediately above the

formation at the bottom of the tubing. The inside of the

tubing is open from the bottom to the top of the well, GAS COMPRESSOR OIL AND GAS

PRODUCED

but in some cases, it may have a standing valve. This GAS IN

prevents backflow from the tubing to the lower part of

the wellbore when gas injection is stopped.

The packer is used to stabilize the fluid level in the

casing annulus and prevent injection gas from blowing TUBING VALVE

around the lower end of the tubing in wells with a low

flowing BHP. The packer is particularly important for

gas lift when the injection gas line pressure varies or the

injection gas supply is interrupted periodically. When

the installation does not include a packer, the liquid that

accumulates in the annulus must be displaced after each

shutdown. Any changes in the injection gas line pres-

sure causes the working fluid level to oscillate unless

a packer is set. This causes additional flow of liquid

through the lower valves and possibly more wear of the

valve seat and stem. RESERVOIR

Figure 10.1 illustrates a typical continuous injection

gas lift well showing that gas is being injected from the

bottommost valve (known as the operating valve) while Figure 10.1 Typical continuous injection gas lift well

For distribution by Petroleum Extension-The University of Texas at Austin

10-1