Page 11 - A Primer of Oilwell Service and Workover Completion

P. 11

LOGGING AND TESTING A WELL

Petroleum Extension-The University of Texas at Austin

LOGGING AND TESTING A WELL

ogging and testing wells DRILL STEM TEST

L occur during drilling, com-

pletion, service, and work over. The drilling crew runs a drill

Logging and testing specialists stem test (or DST) to test a for-

use many types of instruments mation it has just drilled into. PRODUCTION

VALVE

and techniques to reveal infor- The DST gives accurate data

mation about the condition and about a formation’s pressure and

location of the reservoir, forma- the composition of the fluids in

tion fluids, wellbore, circulation it. A DST tool is run in on the

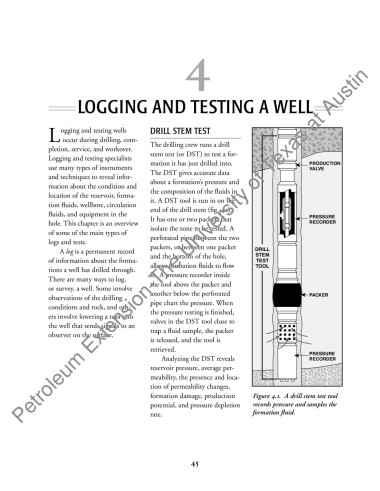

fluids, and equipment in the end of the drill stem (fig. .). PRESSURE

hole. This chapter is an overview It has one or two packers that RECORDER

of some of the main types of isolate the zone to be tested. A

logs and tests. perforated pipe between the two

A log is a permanent record packers, or between one packer DRILL

STEM

of information about the forma- and the bottom of the hole, TEST

tions a well has drilled through. allows formation fluids to flow TOOL

There are many ways to log, in. A pressure recorder inside

or survey, a well. Some involve the tool above the packer and

obser vations of the drilling another below the perforated PACKER

conditions and rock, and oth- pipe chart the pressure. When

ers involve lowering a tool into the pressure testing is finished,

the well that sends signals to an valves in the DST tool close to

observer on the surface. trap a fluid sample, the packer

is released, and the tool is

retrieved.

PRESSURE

Analyzing the DST reveals RECORDER

reservoir pressure, average per-

meability, the presence and loca-

tion of permeability changes,

formation damage, production Figure .. A drill stem test tool

potential, and pressure depletion records pressure and samples the

rate. formation fluid.